Cutting-edge DTF Printing Solutions: Improve Your Clothing with Direct-to-Film Modern Technology

Cutting-edge DTF Printing Solutions: Improve Your Clothing with Direct-to-Film Modern Technology

Blog Article

Ultimate Guide to DTF Printing Techniques for Sensational Fabric Styles

Starting the journey of understanding DTF printing strategies can open a globe of opportunities for producing visually fascinating textile designs. As the fabric industry remains to develop, staying in advance of the curve with innovative printing approaches is important. In this overview, we will discover the detailed information of DTF printing, from understanding the essential fundamentals to unraveling progressed shade techniques that can raise your designs to new heights. Remain tuned as we explore the subtleties of picking the appropriate products, improving the printing process, and conquering typical obstacles to achieve magnificent results.

Recognizing DTF Printing Fundamentals

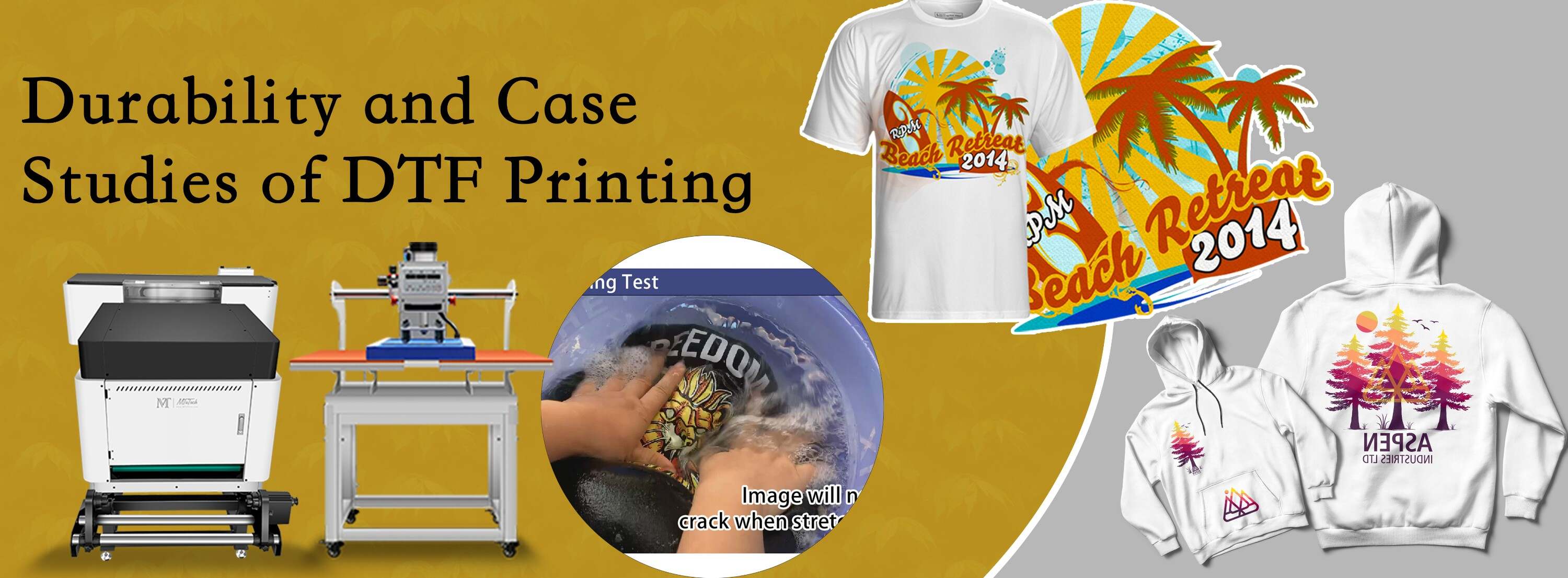

DTF printing, a procedure that includes moving designs from a special film to fabrics using heat and pressure, develops the foundation of fabric printing strategies. The initial step in DTF printing entails creating or choosing a layout that will be published onto the textile.

When the layout is published on the film, it is then very carefully placed onto the textile, ensuring proper placement and positioning. The next important action includes applying heat and stress utilizing a warmth press equipment. This procedure turns on the dyes or pigments on the movie, triggering them to sublimate and bond with the textile fibers permanently. The outcome is a magnificent, long-lasting textile design that is cleanable, flexible, and immune to fading. Overall, comprehending the basics of DTF printing is important for grasping this modern-day textile printing method.

Choosing the Right Fabric Products

Having developed the foundational principles of DTF printing techniques for textile designs, the next vital consideration lies in picking the ideal textile products to complement this innovative procedure successfully. In addition, the stretchability of these materials can accommodate the warmth transfer procedure included in DTF printing without distorting the design. By choosing the right fabric products, developers can make the most of the capacity of DTF printing to create spectacular and lasting fabric layouts.

Grasping the Printing Refine

To master DTF printing methods for textile layouts, understanding the printing process is crucial for accomplishing high-grade and regular results. The printing process in DTF includes a number of vital actions that require accuracy and attention to detail. Preparing the artwork for printing is critical. This consists of ensuring the style is correctly sized and placed for the fabric. Next, the layout is published onto an unique DTF film utilizing a compatible printer with the right setups to achieve optimal shade like this vibrancy and clearness (DTF Printing). Once the style is published, it is then moved onto the textile making use of a heat press equipment. The temperature, pressure, and duration of heat application should be carefully managed to guarantee appropriate bond of the design to the textile. Furthermore, mastering the peeling off process after warm pressing is crucial to stop any type of damages to the layout or fabric. By have a peek at this site developing each of these action in the printing process, developers can regularly produce sturdy and magnificent fabric layouts with DTF printing methods.

Enhancing Layouts With Shade Strategies

Moreover, experimenting with color gradients can bring a feeling of movement and fluidity to the layout. By mixing colors perfectly, a slope effect can be accomplished, including a dynamic and contemporary touch to the fabric design. Furthermore, making use of color blocking methods can create bold and striking visuals by juxtaposing different strong colors in distinctive areas of the style.

Furthermore, integrating metallic or neon colors can supply a unique and eye-catching component to the fabric design, making it stick out and emanate a feeling of vibrancy. When purposefully applied, these shade methods can boost the general aesthetic charm of fabric designs, making them much more fascinating and memorable.

Troubleshooting Common DTF Printing Issues

After discovering various color techniques to improve textile layouts, it is vital to deal with usual DTF printing concerns that might arise during the production procedure. In addition, concerns with photo quality and intensity can take place due to low-resolution images or inappropriate printing techniques. By being aware of these common troubles and carrying out the needed troubleshooting actions, you can improve the general quality of your DTF printed fabric layouts.

Verdict

To conclude, mastering DTF printing strategies is crucial for creating stunning textile designs. Source By comprehending the fundamentals of DTF printing, selecting the best products, and improving designs with shade methods, one can accomplish excellent outcomes. It is necessary to repair typical concerns that may emerge throughout the printing procedure to make sure a successful outcome. With technique and interest to detail, one can produce beautiful and distinct fabric designs utilizing DTF printing methods.

DTF printing, a procedure that entails transferring designs from an unique movie to fabrics making use of warmth and pressure, creates the structure of textile printing strategies.Having developed the foundational principles of DTF printing methods for textile designs, the next essential consideration exists in picking the ideal textile products to complement this ingenious process efficiently. By picking the best fabric materials, developers can optimize the potential of DTF printing to produce stunning and resilient fabric designs.

To excel in DTF printing methods for textile designs, understanding the printing procedure is vital for achieving consistent and high-grade results. DTF Printing. By sharpening each of these actions in the printing procedure, developers can regularly create magnificent and resilient textile layouts with DTF printing strategies

Report this page